1972 Chris Craft 41 Commander Repower

- John Mario

- Sep 10, 2023

- 17 min read

Updated: Feb 4, 2025

After several years limping along tired, problematic 427 gas engines, I decided its in everyone's best interest to repower the boat.

For those of you who have been through it, its akin to gutting the kitchen and every bathroom in your house at the same time. For a transitory period, the boat becomes crusher food - derelict. I'm sure every yard has seen hundreds of these projects start and few complete, especially old boats. I'm about to become one of the few.

Not a great picture, but here's the old girl: 1972 41 Commander, hardtop, hull #004. She was delivered to and sold by Blue Lagoon Yacht Sales in Michigan in spring of 1972. It lived its entire life out on the Great Lakes as "Creative Juices", then "La Mer" and now "Viaggio" ("Journey" in Italian, and boy has it ever been one). She was brought east to the Connecticut River where she spent two years before we bought her. She is now home in New England, soon to be cruising Narragansett Bay, Cape Cod, Martha's Vineyard, Nantucket and beyond.

The boat had been pretty well looked after by the previous owner, but void of any major upgrades for at least 20 years. The engines have proved to be a real challenge. They have somewhere between 1200-1500 hours, but they leak just about everything, they run warmer than they should (Chris Craft's subpar closed cooling system design) despite thousands of dollars in

parts, and they are simply limiting our plans as a family to confidently take her on long trips.

Mike Hagler can attest to the faithful day last fall where I texted him and said "That's it - I've had enough. I'm repowering".

The purpose of this blog is to take you all along for the journey and hopefully provide some help to those who are considering a repower but have too many unknowns to pull the trigger. I expect there will be lots of swearing and aggravation, but if I can survive this then we will have a boat that we can reliably cruise the Northeast as a family.

Where do I start?

Well, I knew it was best to stick with gas engines. Sure, diesel would eventually pay for itself, but for the 50 hours or so a year we use the boat, the ROI was not quick enough to compel me to replace two engines, a generator and replace the tightly integrated factory fuel tanks. Remember, I'm not looking to get into a multi-year restoration. If all goes to plan, I intend to knock this out between layup and launch inside of one year. So gas engines it is.

After feeling the pain of all things unobtanium when it comes to marinized Ford 427s, I wanted engines that had a robust aftermarket of parts with no end in sight. Easy: big block Chevys. Well, I also wanted more power. 300 hp gas engines were borderline underpowered for 27,000 lbs of fiberglass and Formica. I wanted something that could propel the boat to the WOT speeds of the 427s but at cruise RPMs. The only way to get there from here is more torque. I looked at 454s and 502s to start, but the torque numbers were not good enough. I decided a 454-based 496 with the added stroke will output the required torque to afford a drop in gear reduction from 2.5:1 to 2.0:1. The search was on.

I looked at buying two long blocks. I didn't love the what was available on the marine crate engine market. Most had 1 year warranties and were rebuilt in bulk in other countries and imported back into the US. I decided to take an unorthodox approach, one that would make marine purists cringe. I started shopping the automotive crate engine marketplace. Now before you flame me, hear me out: The engines are closed cooled which means there are no fancy bronze cooling inserts or head gaskets necessary. Less those items, there is absolutely no difference between an automotive engine and a boat engine.

I knew I wanted something with super low compression and cast iron heads. I came across Blueprint Engines out of Kearny, NB. They are a high performance crate engine supplier that machines, builds and dyno's each engine under one roof. The idea of buying and engine that has been dynoed (complete with dyno sheet), oil filter cut open and inspected for carnage, ISO9001 compliant, etc. ahead of it arriving at my doorstep was attractive, especially with what a pain it is to get and the engines in and out of the boat if they were DOA. One thing about BPE is they don't customize engines. They have a handful of proven designs and you pick the one you want. I looked at their marine offerings, but they were geared towards go-fast boats complete with high compression and big lumpy cams. I looked at their street engines and found one that would work:

496 CI

Cast iron peanut port heads

8.5:1 compression

460hp/580lbs tq

Problem - discontinued. Ugh. Why, seems they went to a newer version that uses a brand new BPE block casting and aluminum heads, where the discontinued version used what they refer to as a "seasoned, hand-picked block", meaning a used block. The newer version had higher compression which would not have made it good for the application. Back to the drawing board.

Cruising eBay one day, I found a brand new pair of the now discontinued engines in the crate from BPE. Turns out they had a couple left and decided to liquidate them to a reseller they use. At first I was apprehensive because I wasn't buying directly from BPE and there was absolutely no warranty on these. However, they were still shrink wrapped and in crates with all the factory paperwork and dyno sheets. I won't share details, but I paid less than half of list price for these. I quantified the risk that even if there was something wrong with them I could probably get them rebuilt and be at or below the cost of new. So I pulled the trigger and bought them.

Special Delivery

I also bought seemingly the last set of ZF 68A 2.0:1 ratio transmissions in stock in the world, so needless to say it was an expense month, but I was excited!

Engines and transmissions arrived and my son helped me get them on to the build stands.

Cam Swap

The only thing stopping me from bolting up accessories and firing these up is the cam selection. The valve event overlap on the BPE cam was such that I would surely get water reversion in a wet exhaust. Water reversion occurs when the exhaust valve closes after TDC on the exhaust stroke. At low exhaust gas velocities seen at idle, this can actually cause the cylinders to suck water back in similar to the way a syringe takes up liquid. One can image the havoc that could wreak on an engine. Mercruiser had this issue on their HP500 cams to the point they "fixed it" with a TSB telling owners to raise the idle to 850-900 to keep the exhaust gas velocity enough so to reversion does not occur.

The engines came with hydraulic flat tappet cams. After much deliberation and reading the horror stories of modern oil wiping out non-roller cam lobes, I decided to bite the bullet and convert to roller cams.

I chose a cam that makes big torque and nice flat curve (dyno from low compression 350 using this cam below). I hope to cruise around 3200 and 4400 WOT.

7/23/23 Update:

Well, I have a theory that my friendly FedEx guy has it out for me. Without fail he leaves our packages in snowbanks, in front of garage doors directly in the tire path or in the image below, directly under a gutter downspout. Well, Mr. Fedex guy, the joke is on you this time - these are the new WATER PUMPS ;)

His brown competitor dropped off the new Weiand Street Warrior intake manifolds and backordered pushrods.

I chose the Weiand Street Warrior intake manifold because its the only intake manifold that is port matched for peanut port heads. Could I have gone with a rectangular port variety like the Edelbrock Performer 2.0 or Air Gap? Sure, and the results probably would have been comparable. So why the Street Warrior? Because its just a better match. When an intake manifold and a head are port matched it reduces turbulence in the intake path and creates a tick more power and better low end response. The Street Warrior is the only aftermarket intake manifold designed specifically for peanut port heads.

Its summer - time for a break. Take the family out for the day in the Commander. The 427s ran surprisingly well this weekend. They must know they're days are numbered and they are quietly trying to get me to reconsider. Too bad for them that 3 years and two tows later, they have lost their opportunity to impress me.

Back to the garage, Theo knows how important it is to keep his nuts out of the engine. He taped up every place a nut, bolt or washer could fall into. I rebuilt an engine in highschool that blew up because a lockwasher was dropped down the intake at some point during reassembly. 30 years later, I am still super careful.

With the intakes and water pumps installed, we toss the valve covers back on temporarily. Those will be taken off just before starting each engine to check for oil at the top end when we prime the oil pumps.

Well, that's a wrap for now. They are really starting to look like engines! Note the Mercruiser alternator bracket on the port engine. I bought this one used online. I think its a better design than the Crusader alternator bracket. These engines will have a mix of the best of everything. That's the beauty of doing things on your own terms.

Next I will be ordering crank and water pump pulleys and getting one engine's accessories mocked up. I will be using a crank-mounted raw water pump so only water pump and alternator will be belt driven. I have a pretty awesome plan for the oil and trans cooler setup, so stay tuned for that. Happy boating for now!

8/3/2023 - Raw water pump, accessory brackets and pulleys

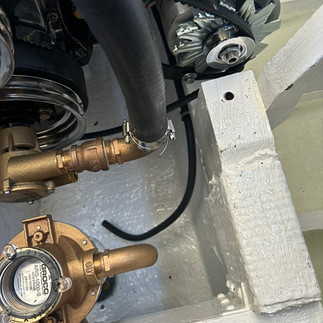

I knew from the word "GO" that I wanted to go with a crankshaft mounted raw water pump. Impeller changes are a pain on the 427s, and from the looks of it Crusader 454s are no better. I decided on the Johnson F6B-9 high flow crank-driven raw water pump.

Now, here is a very important detail: These pumps were made to work with factory short water pump crankshaft pulleys exclusively. The hub (black bit in the picture) needs to be perfectly concentric with the crankshaft pulley or else it will oscillate and probably beat itself to death. There is no locating feature in the center of the hub. I was surprised by this because the crankshaft pulley had a centering feature of its own that created concentricity with the harmonic balancer. Instead, this particular pump need two alignment features on the crankshaft pulley, which are only present on the factory style. Notice the two large raised holes on the face of the crankshaft pulley and the respective locating features on the raw water pump. I ordered an anti-rotation bracket with one end that bolts to the face of the engine block and the other end slips over the threaded boss on the bottom of the raw water pump. A bolt and washer secure the bracket to the boss.

If I could offer one suggestion, buy all new fasteners! For less than $100 I purchased a huge assortment of 3/8"-16 nuts, bolts, flat washers and lock washers. 90% of the bolt-on items use this size and pitch.

As I mentioned earlier, I decided to go with a Mercruiser inboard alternator mounting bracket. Its a better design in my opinion. I could have easily purchased alternators with the 2" ear and be done with it, but I purchased two brand new alternators for the 427s with one installed this season and the other still in the box and I wanted to repurpose them for this build. This required some creative fastening techniques. I used a 3-1/2" long 3/8-16 bolt with a bushing for the oversized mounting hold in the alternator, then a spacer to take up the remaining inch that the proper Merc alternator would have occupied. The lower alternator bracket takes a single 1" long 7/16"-14 bolt. The hardware cost a whopping $16 which saved me about $300 in new alternators.

Finally a little wire to determine the "no-fly zone" for hoses. I'm pretty sure I'm going to thread the raw water pump discharge hose through the belt loop opening between the crank and water pump pullies and the alternator pulley. From there we go up. Spoiler alert - I think I'm going to mount my oil/gear cooler on top of the port side valve cover - more on that later.

8/6/2023 - Freshwater cooling design

Small update today. Got the Crusader thermostat housings in this week along with the 160 degree thermostats. I went with Crusader thermostats because they have the critical bypass hole in them that not all the automotive style thermostats have. The hole allows for trapped air to get to the top of the system and "burp" out. This is especially important on freshwater cooling applications.

I also temporarily mounted the heat exchanger on one engine and started mocking up the combo oil/transmission cooler.

9/10/2023 - Oil cooler, manifolds and risers installation

The best part about this repower is that I'm not working against the clock to get them in the boat. This affords me the time to be pragmatic with the marinization of these 496s. Before I forget, you may or may not have noticed that the valve covers got a haircut. Turns out the tall BBC valve covers do not clear the marine manifolds, so I had to swap them out with short valve covers. This was inconsequential because the valvetrain is stock so I didn't have roller rockers to contend with.

Previously, I mocked up a port side valve cover mounting location for the oil cooler. I had planned to snake a 1-1/4" hose from the outlet of the raw water pump, through the drive belt and up to the inlet of the oil cooler. Marine Power did this successfully with their 454 model but it required a very unique molded hose. Keeping with my goal of using as much generic silicone heater hose as possible, I opted to move the oil cooler to the starboard side valve cover and make a simple loop up to it using silicone hose. First order of business was to weld some studs to the valve cover so my trick Hardin marine oil cooler mounts could be fastened to it.

I decided to go with Mercruiser style manifolds and risers. Reason one is they are proven, common and offer better clearance for my application. Reason two, is Crusader manifolds and risers are in short supply at the time of this build and I didn't want to install anything that showed any signs of being hard to get. I also went with a Mercruiser style oil filter housing. I like the access to the oil filter over the Crusader which is back by the bellhousing. To make the closed cooling hoses work for this application, I must elevate the oil filter housing a bitoff the riser base. I used two threaded rods and some nuts to model up the exact height. A permanent spacer will be made thereafter.

Getting all the correct fittings for the coolant and raw water hoses was tedious but what I came up with looks decent and will do the job. Using the Crusader heat exchanger with the Mercruiser manifolds created a cooling hose size mismatch. Crusader uses 1-1/4" coolant hoses on their heat exchangers and risers while Mercruiser uses 1". I had to neck up from the manifolds to the heat exchanger. No big deal, but added some additional threaded plumbing bits to the equation.

Before I forgot, I wanted to get the dipstick routing ironed out as I figured it would be better to claim space now rather then try to squeeze it in later. A pleasant surprise was that one engine had a port dipstick oil pan and the other a starboard dipstick oil pan. Lucky! This allows access to both dipsticks from between the two engines. Built a little bracket for the tube, splashed it with black paint and considered it done!

Next was the oil cooler and transmission lines. -12AN for oil and -8AN for transmission. The -12AN size is a bit of pain to work with because the fitting are just so big. However -12AN is necessary to maintain the 1/2" pipe ID required for proper oil circulation with minimal pressure drop. I had a 1406 Edelbrock hanging around so I mounted it temporarily to ensure there was no interference with any of the oil hoses. My daughter came out on Saturday night to listen to some tunes and keep me company. Even touted her shop rag artwork :)

11/6/2023 - Gears, distributors and the great extraction

Its been a busy couple of months with the project. I did the final fitting of the oil cooler lines, the gears and all the remaining accessories. I went with another set of DUI distributors after having great luck with the first set for the 427s. A quick call to Gene at DUI and 10 weeks later they are on my doorstep complete with their LiveWires spark plug wires.

I spent nearly a month trying to figure out the best way to remove the existing engines from deep in the cabin sole. Unlike the earlier 42 DC models, the 41 does not have a side cabin door. This makes access difficult for heavy equipment such as forklift forks. This leaves two options, cut a hole in the cabin roof and pick the engines with a crane, or rig up a gantry system and get the engines broken down enough so they can pass through the 25" wide aft cabin door.

I have to say I was totally overwhelmed with both propositions, but Mike Hagler talked me off the ledge and helped me formulate a plan to avoid cutting the cabin roof. Mike flew from Michigan to Massachusetts to help me, which was probably the nicest thing a friend has done for me in a long time, maybe ever! Like most guys, we spent a solid afternoon taking measurements, sketching and plotting our plan. In the end, the design was quite simple.

To get the engines out of the engine beds, we purchased a 1000lb capable sawhorse and some 4x4s and 2x4s from the local home improvement store. We estimated that we needed 40" of height from the floor to the bottom of the 4x4s, so Mike crafted up some blocking out of 2x4's. The 4x4 beam traversed the side window and blocking was affixed between it and the side exterior deck. With the heads, manifolds and risers removed and everything disconnected, we pulled the old girls out of their tombs of 52 years and onto the salon floor.

Halfway there - next step is to get them out of the salon and onto the aft deck. We decided to split the gears from the blocks to lighten the load as we weren't yet confident about the weight capacity of our gantry going aft. The aft gantry was pretty similar in design with a sawhorse aft blocked to the correct height for the engines to clear the cabin door threshold, and a 2x6 spanning from the sawhorse to the cabin top. Mike had he forethought to anticipate dragging a chain carrying 600lbs of Ford big block down the length of a piece of timber was going to be difficult. To overcome friction, Mike crafted a makeshift roller that served as a bearing in that it elevated the chain from the plank. For good measure, we socked in a eyebolt to the opposite end of the 4x6 plank. We connected one end of a comealong to the eyebolt and the other end to the load bearing chain. The idea is to pick the engines straight up from the salon (or as close as possible), then use the comealong to traverse them aft along the plank. All I can say is wow, it worked!

Winter 2023 - Lets finish up the engine builds!

With the holidays and a rather large shop reconfiguration, the project stalled out for about 8 weeks. Next on the docket is to wire 'em up and fire 'em up. If anyone knows me, I'm a bit OCD about clean wiring and this project was no different. A quick design in AutoCAD Electrical, a few boxes of assorted connectors, some wire and labels and I was off to the races

Time to break them in at the shop. I recommend this exercise to anyone before the engines get installed in the boat. I had a defective lifter, starter and riser between the two engines, all things that were easily addressed in the comfort of a warm shop and not in a cramped engine room!

Spring 2024 - Prepping the boat for the new power

I left a hell of a mess of the boat as we scrambled to get the old powertrain out before the snow flew. I would define it at the quintessential "rode hard, put up wet" situation.

Shafts

I decided now was the time to upgrade from the factory shafts to a fresh set of 1.5" Aquamet 22 shafts complete with BA couplings. With the nearly 600 pound-feet of torque produced by the new mills, modern materials were required to reach the recommended safety factor of 4 for recreational gas engine applications. The original coupling on the starboard side had spun on the shaft and welded itself to the shaft so I had to take the nuclear option for removal. They went in smoothly and the PSS shaft seals were replaced with Lasdrop Gen II's. I ended up ordering the shafts 6" longer than factory because the short ZF gears place the engines farther back, making access to the coupling miserable. This proved to be a wise decision.

Adding Additional Cutless Bearing

The 41/410 Commander prop shaft support system has a significant design flaw. There is a maximum span of unsupported shaft length permitted based on RPM before the shaft can start "whipping" (imagine a jump rope swinging). As you can imagine, this is not only hard on the cutless bearings and shaft struts, but on more brittle materials such as AQ22, it can cause shafts to fracture.

The 41/410 come equipped with shaft logs that are just the right size for a 1/2 length cutless bearing to be pressed in. This added support reduced the span between the coupling and the first cutless bearing by 50%, which put it well within the unsupported span limit.

Engine Mock-up

With the shafts in place, it was finally time to set the new engines. Instead of breaking my back fumbling 800lbs of propulsion around the engine room, I decided instead to buy foam replica engine block from Summit Racing. The mock up block comes complete with threaded holes for everything, so I was able to mount the mounts, bellhousing and transmission to it for a total weight of 60lbs. I had the whole setup in and out of the engine room at least a dozen times so I was happy to have lightened the load.

The 427s mounts came of the front of the engine where the 496s came off the side so there was some trimming and shimming to do. Not to mention, the transmission output is down angle vs the factory Paragons which were straight. As such the new engines ended up sitting relatively flat vs their nose high predecessors. Shims were made out of white oak butcher block.

Prep for Paint

Knowing that this would (hopefully) be the last time I have this kind of unfettered access to the engine room area, I really wanted to epoxy coat everything to brighten it up and provide added protection. After much research and a call to a pro in the business (thanks Jeremy at Custom Boat) I opted for a product called Aquagard300. It is a catalyzed two-pot epoxy like any other but does not contain solvents so it is virtually odor free and is every bit as tough as competing products. It goes on pretty thick so I did throw a splash of acetone in with each batch to make it flow out better. The engine room was very dirty and I ended up spending a solid week just degreasing, cleaning and sanding to make sure the epoxy had the best possible surface to bond to. Overall I was pleased with the results.

Install Day

With some help from the yard team at the marina, we got the engines on deck, down to the salon and thunked down on the engine mounts. I could not have asked for a smoother operation!

Death by a Thousand Cuts

I was bit by the "while I'm in here" bug throughout the final stretch of this project. I took the liberty to guy most of the factory engine room wiring, run all new copper fuel line, reconfigure my battery banks, paint, and the list goes on. I'll toss some pictures down here of a few of these projects, but won't go into much detail because the repower would have been successful without doing any of this.

Let's Go!

On a rare 70 degree late October day in 2024 on Narragansett Bay, Mike H and I sea trialed her. We stopped and grabbed some fuel and headed out. I will say, taking a big untested boat out for the first time is nerve-wracking but with Mike's help I was confident we could handle whatever she was going to throw at us.

We idled through the no-wake uneventfully and entered Greenwich Bay where I began to apply some power. The boat responded eagerly and popped right out of the water and onto plane. It was the first time the boat had been on plane in many years and it produced a nice smooth ride. For those who say these 41/410s ride choppy probably have never gotten it out of the water. Its a night and day difference.

Below are some videos Mike grabbed. We quickly determined the boat was overpropped with the factory 22x22 wheels after the engines failed to reach WOT rated RPM of 4400-4600, achieving only 3200 RPM. At 3200 RPM the boat reached 23 MPH, and I am confident low 30's is entirely possible with the new props I purchased for next season.

Closing Arguments

Well, as with any boat project, this one was way more work than I expected. The end result was rewarding though. It took careful planning, patience and a bit of trial an error. There is no instruction manual for installing a modern engine in an obsolete boat. Let common sense prevail and try not to get too hung up on the what-ifs. Get a great network of Commander owners from the Styled in Fiberglass and the Chris Craft Commander Owners Facebook Groups for moral and technical support and you will be amazed at what you can do!

Big shout out to Mike Hagler for the multiple trips from MI to MA to help with the repower!

I have enjoyed watching the progress on this. I thought I would share a specific experience of mine that may help you. I have a 1973 41 Commander Flush Deck. Most of the documentation I have shows construction in late 1972, so very similar to yours. It was re powered years ago (early 2000s or late 90s) with 80s era Crusader 454s. I do not have the mechanical experience you do, but was smart enough that I wouldn't have purchased the boat with the original raw water cooled Fords (we live in NC and we are very close to salt water). I replaced the Crusader manifolds due to cracked risers and inability to separate the elbows due …