41 Commander Helm Refit

- John Mario

- Aug 10, 2023

- 6 min read

Between the flakey gauges, the intermittent switches and the non-existent alarm buzzer I have decided scrap the Total Command System in my 1972 '41.

First I will preface that this is not a project for the faint of heart. However, I am lucky enough to have the original schematics for the boat, along with the TCS service manual. It really comes down to a matter of confirming what is there from the factory, what has been removed and what has been dealer/aftermarket added. Luckily, Viaggio is pretty original minus an updated fume detector, and a (dealer installed?) Benmar Course Keeper.

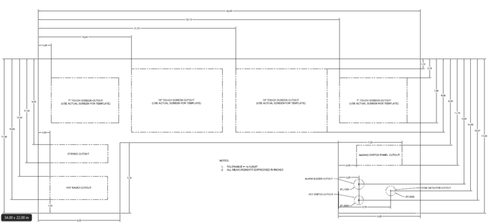

As an electrical engineer, for once with my boat, I am right in my wheelhouse (no pun intended). With schematics in hand, I have been working on the new helm design in CAD. My plan involves removing the TCS circuit breaker/junction box unit. Yep, the one that's door cannot be opened with the helm installed....not one of Chris' finest engineering accomplishments. Everything runs to and from this box. Each switch receives power from this box, and the load is switched back through this box on out to the consumer. The result is a hundred extra connections to corrode and seemingly miles of wires to trace.

The good thing is that all of the ships' systems are terminated to terminal boards at the helm before connection to the box. This makes for a tidy break point between old and new. The engine harnesses home-run from the box to terminal boards in the engine room, so I will be cutting off the TCS connectors at the helm and installing new terminal boards there. The result will be the ship side totally terminated to terminal boards at the helm.

The circuit breakers on the new design will be integrated into the gauge panel (where they should be in my opinion). For now, I have marked what couldn't be found on the schematics and pulled the dash today:

The purge begins... Well, I am deep into the abyss called the Total Command System and I found some very interesting things. First, my conspiracy theory, then an explanation:

the terminal board at each engine straight to the jack on the TCS box at the helm without terminating anywhere in between. The non-TCS system has conventional terminal boards at the helm which circuits from the engines terminate on one side, and the helm gauges and switches on the other.

Well, lets just say my boat is "special". Its special in the fact that my hull was originally wired for non-TCS, with TCS added later in the manufacturing process. How do I know? Well, lets just say my helm terminal boards have the non-TCS engine harness wired to one side of the terminal boards (confirmed wire numbers on the non-TCS schematic), and virgin, never been used empty connections on the other side of the terminal boards. I found the other end of the non-TCS harnesses coiled up in the engine room in a very original way!

Let's reinforce my theory shall we? All of the wire numbers and colors at the engine room terminal board jive with the non-TCS schematic.

The Design - Rolling My Own

I knew I wanted to do a home-grown solution. I never liked the engine "gauges" on commercially available NMEA2000 MFDs. They were never the right size, colors or style in my opinion. I wanted something that was graphically rich and laid out exactly the way I wanted it. As such, I harnessed several decades of electrical and software design experience and got to work.

The existing helm panel makes for a great template for the new one. First order of business was to determine how many screens I could fit. I settled on two 10" and two 6" screens for my gauges and "soft" buttons. I added "hard" buttons for engine start/run/stop, battery parallel and anchor light for things that I either couldn't or wouldn't let a computer manage. Other features include a new stereo, gas vapor/heat/bilge monitor and VHF radio.

I took the CAD drawing to a local countertop maker and had a new helm panel cut from Corian with all the required cutouts.

Digital Switching

I have yet to see an elegant NMEA2000 digital switching solution, which is probably why I seldom see digital switching adopted on these types of projects. So I opted to replace the TCS circuit breaker box with three Eaton power distribution centers designed for use under the hood of big rigs. They are mil-spec for vibration and IP68 for water ingress protection. These communicate on CAN BUS which allows both control and monitoring of relays and fuses.

Electrical Design

Another thing that grinds my gears is when wiring jobs are performed and nothing gets documented! Using photos, and each set of (conflicting) factory wiring diagrams, I began the daunting task of documenting what is there and will be reused and what is new. I drafted all new electrical schematics using AutoCAD Electrical.

I feel like the project is really turning a corner a now, and best of all its 100% documented. This means that if I ever sell the boat or simply forget what I did in years' past (not out of the question with me), I can turn to the electrical schematic I created in CAD.

All the wires are numbered and reconcile with the schematic. Additionally, all new port battery wiring starts with 1000 and starboard 2000. This way I can look at wire 1002 for example, and know its fed from the port engine battery.

Some Assembly Required...

Now, don't get me wrong - gutting the boat electrical system like a fish still gives me some anxiety, but keeping the tasks small and measurable keeps panic at bay!

Helm panel is all wired up. Next step is to unit test the assembly. Taking a page out of my software engineering book, by unit testing each assembly, the aggregate will work - theoretically of course!

As much as I moan and groan about the TCS, one thing it does offer is granularity on the alarm front. Prior to TCS, each engine had a buzzer and when its buzzing it’s either oil pressure or engine temp - your guess.

I decided to build my own alarm module that breaks out each engines’ alarms into:

Oil pressure low

Water temp high

Drive temp high

Fuel pressure low (a new one!)

The single buzzer and flasher on my helm is triggered from this module. The alarm signals go to the SeaGauge module and on to the helm display. Additionally, the alarm module has status LEDs for each individual alarm. This way if I ever lost the helm display and had to drive “blind” I will have the hardwired alarms functional and should an alarm occur, the LEDs in the alarm module will direct me to the problem.

Lastly, the less exciting part is that I have prepped all my connectors so only the ship side terminations need to be dressed. This should save some time during my increasingly shrinking weekends leading up to the launch.

Software Design and Testing

I settled on developing the software using Microsoft .NET. Its what I'm good with and its more than up to the task. For CAN/NMEA2000 communications, I checked out the open source offerings and they are very impressive. The challenge I have was having NEMA2000 and J3919 CAN devices coexist on the same network. I ended up the drivers from scratch to insure I got only what I needed and nothing more. This kept everything lightweight. I powered it up last night:

A minor update: I’ve had the full CAN network and all devices connected to my helm station for 10 consecutive days uninterrupted. The software is fully vetted. I simulated sensor inputs into the seagauge module and out to my screens, tested every engine alarm, and every NMEA 2000 PGN for accuracy. I also drove the tachometer inputs on the seagauge module with a PWM to ensure signal accuracy. Note the green rings around my tachs - instead of a sync light, the slower engine’s gauge bezel goes gray. If both engines are within 100 rpm of each other both go green. If either engine stalls, a flashing red ring appears.

Install Weekend

On with the new! The last TCS two harnesses remaining are terminated to the ship terminal boards. I plan to literally remove one wire at a time and replace with the new wire. I have all the ship side wire numbers recorded and will be added to the as-built schematic. I started with installing the new Eaton power distribution centers along with the helm power relays and fusing.

A later shot of less TCS and more new stuff!

Last bit of the TCS gone and the behind-helm wiring complete

Dash panel wired in:

More pictures to come!

Great stuff John. With my 66 CCC 38, she was “redone” by the PO in about 2004. The AC wiring is grounded and GFI’d. The DC wiring was redone then, too. However, neither effort was diagramed and there are no labels! The PO hired it done and had no interest how it worked.

Fart forward to the present where I’m wondering what is wired where, and to which side, and my battery charger keeps blowing its fuse on the starboard side leg … ugh! Where to begin?

So my mother-in-law bought me a label writer (she’s very sweet) and I’ve been labeling, diagramming what I can. Love your wiring nomenclature. Learning so much here.

I may one day achieve a…